This description has been translated and may not be completely accurate. Click here to see the original

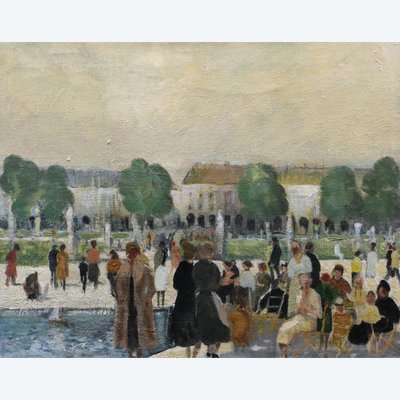

Set of 12 soft porcelain plates from Tournai, 18th century

Famous decoration with a fly and 3 bells in blue

Central decoration with 4 bouquets on the rim

Edges highlighted with a cobalt blue braid

On the back, different brush letters on some plates

Very good used condition: tiny small chips restored on 3 plates (last photo)

Set consisting of: :

8 flat plates d: 23.6 cm

4 dessert plates d: 20.5 cm

For information:

In November 1750, the Lillois F. J. Peterinck sent a request to the governor of the Netherlands, Charles of Lorraine, to be able to establish a porcelain factory in Tournai under his protection. This request was granted, thus giving rise to Tournai porcelain, remarkable for its quality and quantity produced over time. He bought the François Carpentier factory, which he had just set up on the Quai des Salines. This porcelain was intended for all levels of life. Thanks to the so-called "blue camaïeu" porcelain, Tournai created many luxury pieces that were on a par with the finest European productions. Pieces of this porcelain are preserved in particular at the Tournai Museum of History and Decorative Arts.

The first materials used were grand feu enamels, such as cobalt oxides (blue) or manganese oxides (brown) and the rust color, called "iron red". They were fired at around 1,100 °C.

The primary elements in the composition of Tournai paste, clay, marl and chalk, once washed and dried, rested for six months, then were mixed with the previously fired and ground frit. Then poured into vats filled with water and then ground again. This muddy liquid was then subjected to evaporation in dryers.

Two processes were used: molding for flat pieces, which consisted of applying, using a damp sponge, a crust of paste of equal thickness on a ticking on the plaster mold, and casting for hollow pieces, which Tournai was the first to use on the continent. Casting was done by quickly pouring the slip (paste added to water forming a thick liquid), in a continuous and regular jet so that it remained homogeneous.

The imperfections were then retouched. The patterns blurred the grooves and the gadroons, which could be obtained by molding, were applied after the fact. Accessories such as feet, handles, ornaments and reliefs were also molded or cast separately to then be applied to the main piece of slip. Tournai porcelain, which is a special porcelain containing more kaolin and less flux, requires a particularly high firing temperature.

The first firing is around 1,100 °C. It produces the biscuit which may have been previously decorated with high-fire dyes. The resulting object is fragile and porous. After drying, this piece is dipped in a glaze bath which, after firing between 1,300 and 1,400 °C, will give the porcelain its final shiny and translucent appearance.

Among the high-fire dyes, we recognize iron red and especially blue cameos which required only one firing. The biscuit is then covered with a glaze requiring a second firing. The other dyes, also called muffle dyes, such as purple, were placed on the glaze after the piece had already undergone a double firing. In France, gold was reserved for the royal manufacture of Sèvres, Tournai benefited from the privilege of its use and developed a very high quality recipe.

Ref: QIIXBEONYF

Art Nouveau Mounted Shell, 19th Century

1.200 € EUR

Art Nouveau Mounted Shell, 19th Century

1.200 € EUR